NEOVISION

AI-powered computer vision to transform operations

Unlock real-time insights for customer experience, asset protection and workforce safety

Is poor customer experience costing you revenue?

Traditional retail struggles with long queues, inadequate staffing, poor layouts, and lack of personalisation, leading to poor customer experience, inefficiencies, and lost revenue. These issues fuel a cycle of customer frustration, with 78% abandoning transactions and only 1 in 26 providing feedback - most simply leave.

PAIN POINTS

Introducing NEOVISION - CX

Proven AI for enhanced customer experience

NEOVISION - CX uses AI-powered computer vision to analyse interactions from camera footage, delivering actionable insights that enhance customer experience, service quality, and operational efficiency while maintaining privacy and security standards.

PRODUCT FEATURES

PRODUCT APPLICATIONS

-

Analyses arrivals to cut wait times by 40% and boost throughput in high-traffic stores.

-

Uses traffic data to optimise venue layout, increasing sales by 15-20%.

-

Monitors peak hours to balance workforce, reducing bottlenecks and frustration.

-

Leverages demographics for tailored messaging and engagement in venues.

-

Detects sentiment drops to enable proactive service improvements.

-

Tracks queue exits to refine operations and retain 78% of frustrated customers.

PRODUCT BENEFITS

Measurable ROI

__

Increase throughput by 30%

__

Boost sales by 15–20% through personalised marketing

__

Reduce inventory stockouts by 30%

__

Reduced queue times by up to 40%

Success stories

Cinema chain elevates customer experience with our computer vision solution

Our computer vision solution transformed a major cinema chain’s operations. Tracking customer behaviour with 95% accuracy, it assessed demographics, queues and staffing levels for precise real-time data. It reduced wait times, boosted engagement and enabled personalised marketing. The solution cut bottlenecks, increased ticket sales and set a new standard for data-driven cinema operations, enhancing guest satisfaction across multiple locations.

Is manual inspection of critical assets increasing your risk profile?

Manual inspections miss 30% of critical faults and cost 5x more, creating unnecessary safety risks, preventable outages and escalated costs.

PAIN POINTS

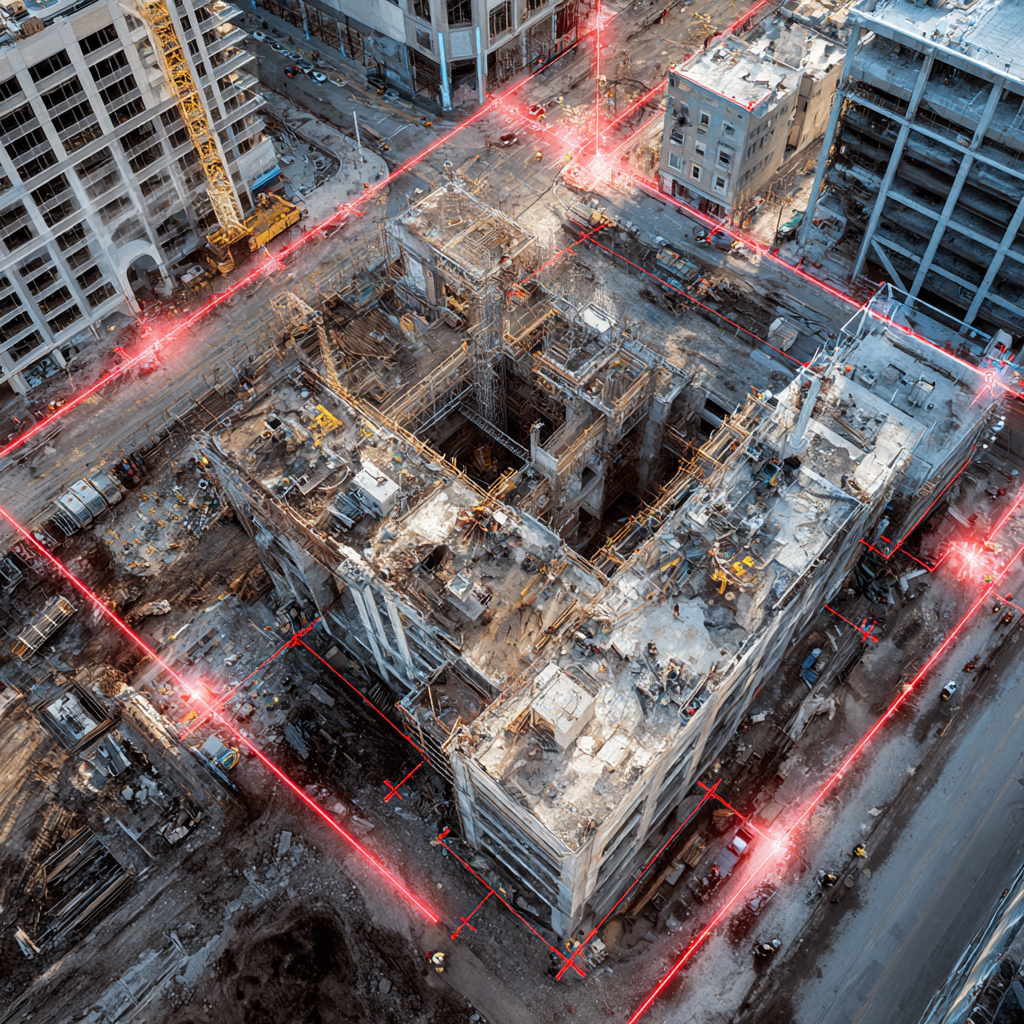

Introducing NEOVISION - VI

Proven AI for enhanced asset monitoring and protection

NEOVISION VI uses computer vision to enable visual inspection at scale, automatically identifying defects, faults and anomalies (leveraging a 40m+ image library), monitoring progress, ensuring material availability, and reducing costs.

PRODUCT FEATURES

PRODUCT APPLICATIONS

-

Detects defects early to avoid outages in energy infrastructure.

-

Provides visual reports for stakeholders to ensure on-time delivery.

-

Monitors materials to prevent delays and cost overruns in projects.

-

Identifies anomalies in critical infrastructure to cut downtime by 35%.

-

Verifies fixes with evidence to minimise rework in maintenance.

-

Tracks progress to optimise labour and equipment in large-scale builds.

PRODUCT BENEFITS

Measurable ROI

__

Improve system uptime by up to 20%

__

Achieve up to 50-60% cost savings on manual inspections

__

Enhance anomaly detection accuracy to 90-100%

__

Reduce outages by up to 30%

Success stories

Utility operator enhances grid reliability with computer vision

A leading electricity provider transformed power line inspections with our computer vision solution. Using drones with visual and thermal sensors, it automated fault detection across 34+ tower components, covering 8,500 towers and 1,000 km. It eliminated human error, reduced hazardous fieldwork and cut maintenance costs and downtime. Automated reports streamlined decision-making, ensuring a reliable power supply and resilient energy future.

Is adhoc safety monitoring exposing your workforce to preventable risks?

Traditional OH&S practices in high-risk industries fail to detect real-time hazards, leading to injuries, downtime and compliance fines.

PAIN POINTS

Introducing NEOVISION - OHS

Proven AI for enhanced safety and compliance

NEOVISION OHS uses computer vision to monitor sites in real-time, proactively detecting unsafe behaviours, equipment misuse, and site risks, providing real-time alerts and automated reporting to ensure safety and compliance.

PRODUCT FEATURES

-

Real-time alerts for violations to reduce accidents by 50% in construction.

-

Generates visual evidence for audits in high-risk industries like mining.

-

Cuts incident times by 70% with proactive hazard detection.

PRODUCT APPLICATIONS

-

Monitors behaviours to prevent falls and stressing in manufacturing.

-

Tracks equipment to avoid misuse and downtime in oil fields.

-

Provides trails to minimise fines and ensure OHS standards.

PRODUCT BENEFITS

Measurable ROI

__

Reduce safety and security incidents by 35%

__

Cut incident response time by 60-70%

__

Improve safety compliance rates by 25%

__

Achieve 95% accuracy in hazard detection

Success stories

UAE manufacturer boosts site safety with our computer vision solution

A leading UAE manufacturer deployed our computer vision solution across a 250,000sqm site with 1,200 workers. It ensured PPE compliance, detected unauthorised zone access and monitored height activities with real-time fall alerts. The system reduced incidents, improved response times, and strengthened safety culture. Centralised analytics lowered risks and liability, enhancing efficiency and improving worker safety and welfare.

Is your reliance on manual workflows limiting field productivity and safety?

Extended Reality (XR) solutions transform guided field workflows by providing immersive, real-time guidance for complex tasks, boosting productivity and reducing errors. With data overlay and remote support, XR accelerates onboarding, enhances safety and boosts productivity.

PAIN POINTS

Introducing NEOVISION - XR

Proven AI for enhanced workflows in the field

NEOVISION - XR uses extended reality (Hololens, Magic Leap) to provide for guided workflows, real-time alerts and remote support for workers in the field.

PRODUCT FEATURES

-

Guides maintenance to cut errors by 30% in remote utilities.

-

Overlays instructions to speed onboarding in skilled trades.

-

Alerts workers to risks during complex tasks in energy sectors.

PRODUCT APPLICATIONS

-

Increases output by 40% through efficient workflows in construction.

-

Provides remote support to scale expertise in oil and gas.

-

Reduces operational delays and labour needs in field operations.

PRODUCT BENEFITS

Measurable ROI

__

Increase workflow efficiency by 35-40%

__

Reduce field errors by 30%

__

Cut operational costs by 20-25%

__

Reduce training costs by up to 50%

Success stories

UK port enhances maintenance efficiency with our XR Solution

A UK Port Company’s 10-week trial of our XR solution transformed maintenance with headsets and thermal imaging. Detecting issues like bearing heat, it reduced engineer dispatches, minimised delays and prevented failures for 100-150 monthly vessels. Integrated with asset management systems, boosted uptime, cut costs and attracted tech-savvy talent, addressing UK engineering shortages while ensuring safer, proactive operations in a 24/7 environment.